ASTM D2872 Uji Oven Film Tipis Bergulir

Merek KN

produk asal Dalian, Cina

waktu pengiriman memberikan segera setelah menerima pembayaran

kapasitas pasokan 30 set per bulan

oven ini menunjukkan perkiraan perubahan sifat aspal selama pencampuran panas konvensional sekitar 150 ℃ seperti yang ditunjukkan oleh viskositas dan pengukuran reologi lainnya. Ini menghasilkan residu yang mendekati kondisi aspal seperti yang tergabung dalam trotoar. Jika suhu pencampuran cukup berbeda dari 150 ℃ tingkat. lebih atau kurang efek pada properti akan terjadi. Oven ini juga dapat digunakan untuk menentukan perubahan massa, yang merupakan ukuran volatilitas aspal

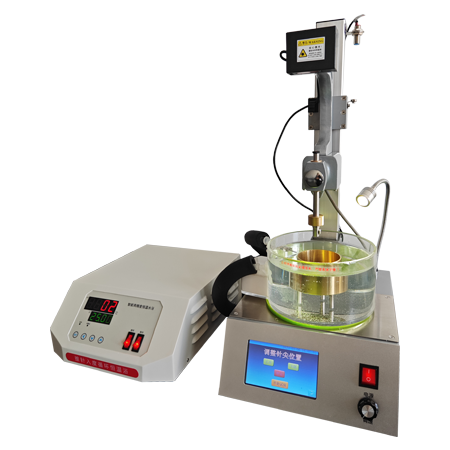

KN-2872 Rolling Thin Film Oven

Overview

KN-2872 Rolling Thin Film Oven is designed on the requirements of the instrument according to ASTM D2872 Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). This oven is used to indicate approximate change in properties of asphalt during conventional hot-mixing at about 302℉(150℃) as indicated by viscosity and other rheological measurements. It yields a residue which approximates the asphalt condition as incorporated in the pavement. If the mixing temperature differs appreciably from the 302℉(150℃) level, more or less effect on properties will occur. This test method also can be used to determine mass change, which is a measure of asphalt volatility.

Features

Adopts thermal insulation layer and duct between the studio and box shell

Stable and accurate temperature control

Filled with aluminum silicate cotton in insulation

Dedicated air machine to supply the required air flow during the test

Temperature sensor of the heating device adopts the advanced ASIC chip and manufacturing technology with perfect performance

Technical parameters

Working temperature: 163℃

Temperature accuracy: ±0.5℃

Heating power: 2KW

Wheel speed: 15±0.2rpm

Air flow: 4±0.2L/min

Bottle nozzle size: 6.35mm

Filled sample bottle size: φ64*140

Studio size: 480*450*380

Rated voltage: 220V±5%